By Valley Organ Restoration Co. LLC

Christopher Schaefer, Corporation President & Project Director. CT business Authoritative Legal Entity ID no. 2911668

towards the restoration of the 1876 Henry Erben organ at St. Patrick Parish & Oratory, Waterbury, Connecticut:

“an instrument of magnificent volume and of perfect tone…a very superior instrument in all respects”. Hartford Daily Courant Sept. 22, 1876

In 1923 it was moved from St. Patrick’s in Hartford to its present location, altered significantly, electrified and unfortunately allowed to fall into disrepair. By 1999 it no longer was functioning, and a low-quality electronic substitute was installed.

Restoration Goal: to have this majestic organ working by 2028—for our church’s 125th dedication anniversary.

֍Monthly Summary updated through December 13, 2025֍

Approximate value (i.e. what most organ companies would charge) for the work listed below: c. $275,000. Amount which Valley Organ Restoration Co has charged your parish thus far, for both labor and materials: $535. Today a new organ of this size and specifications would cost over $1,000,000. (NOTE: The organ currently heard at Mass is an electronic substitute, not the huge pipe organ one can see in the back of the church and which has not been usable for many years.)

Work done thus far:

֍֍New for December 2025: Chris completed the wiring for the solenoid slider motors’ relays (switches) and began work on the Pedal slider motors. Scroll down for photos and explanation.

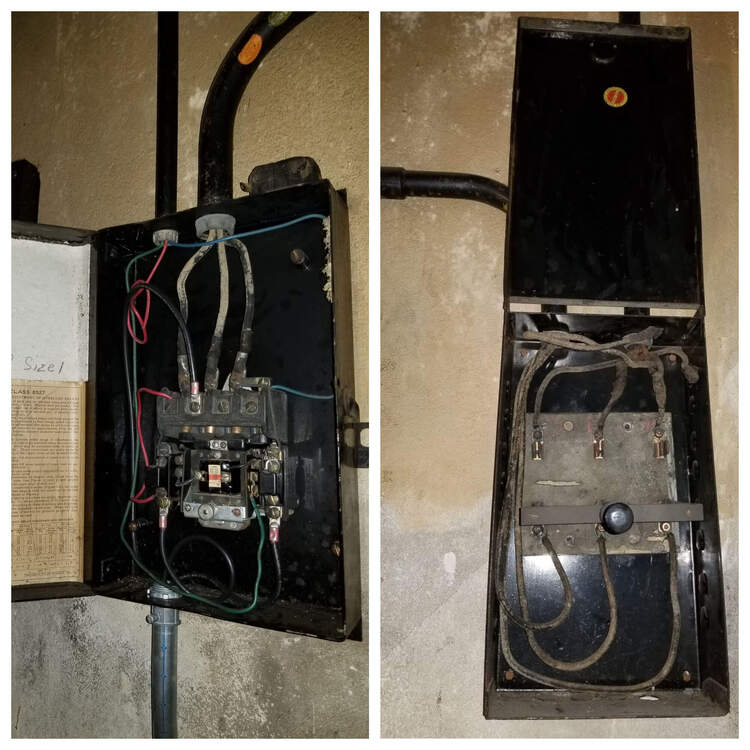

In Nov. 2020 the organ blower room in the church’s basement hall was cleaned for the first time in nearly a century. Several months later, Chris Schaefer (president of Valley Organ Restoration Co) replaced the hazardous 1920s motor starter and shut-off switch in the blower room with a new Square D motor starter and safety shut-off switch for the 1923 OrgoBlow blower’s 3-phase Westinghouse motor. (Motor was rebuilt in c. 1978 and is in excellent condition; the blower provides the pressurized air for the organ pipes.)

old:

new:

In 2021 Chris added a filter box to the main wind trunk, which brings pressurized air from the blower room up to the organ.

Chris installing filter box beneath the organ pipes:

new filter box installed, exposed wires later were properly enclosed:

IN 2024 Chris modified the organ blower room, as well as the organ loft’s entry point of the blower’s air duct (“wind trunk”), so that the blower now draws much of its air from the space between the wood enclosure around the wind trunk, via a grill in the organ loft (pictured below), rather than from the basement/church hall. From the basement blower room the pressurized air then returns to the loft inside the wind trunk (a 12-inch-diameter pipe) and enters the pressure regulators (reservoirs) beneath the organ pipes. Using the same air where the organ itself is located to provide “wind” for the organ will help stabilize temperature, humidity and tuning of organ wind chests, reservoirs and pipes:

From 2021 to 2022, the deteriorating plaster wall behind the entire organ was covered with vinyl-coated hardboard paneling (aka high density fiberboard/HDF) screwed directly to wall studs; all panel joints were caulked.

Pictured below: new paneling on left, deteriorated plaster on right.

Pictured below: Chris Schaefer, president of Valley Organ Restoration Co and project director, atop 24-foot extension ladder, installing paneling behind organ, to cover deteriorated plaster. Virtually every surface of the organ was covered with chunks of plaster and plaster dust.

In 2023, Chris covered the plaster between the large window above organ and Swell & Choir chambers with waterproof cement board, with aluminum drip edge above and flashing below. Earlier, he had covered the top of Swell and Choir chambers with tarps to prevent future water damage. (When this window had leaked several decades ago, it caused water damage inside the organ.):

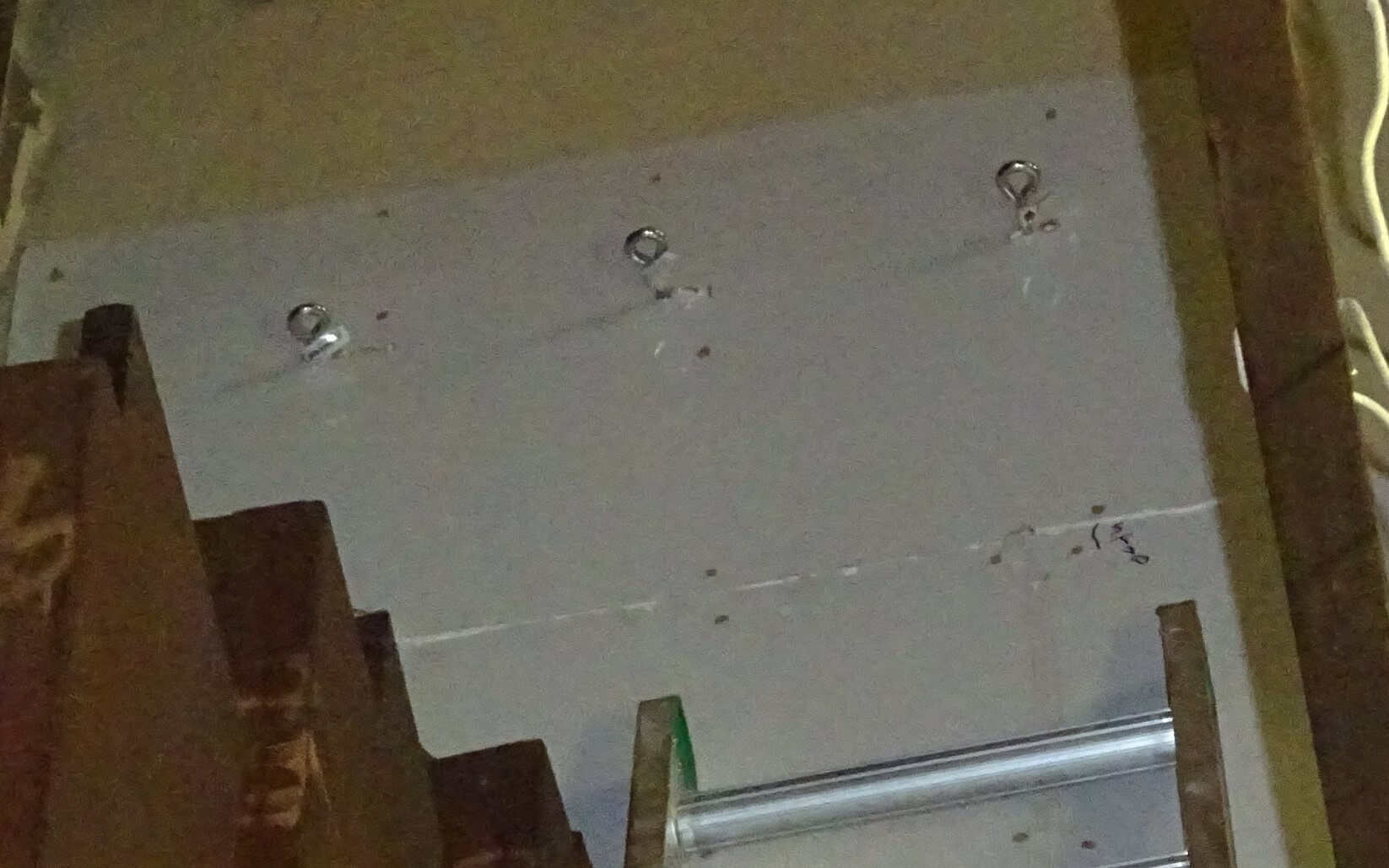

Chris added large steel corner braces to properly secure the sides of organ case to studs in rear wall. He also placed large eye screws into studs across rear wall near top of organ, so next time the ceiling above organ needs repair or painting, protective tarps can be secured to these eye screws and pulled over entire organ. (When the church was repainted some decades ago, paint was splattered over many of the organ pipes!):

From 2021 to 2023 nearly all pipes were removed, one section of the organ at a time, so that chunks of plaster and plaster dust could be vacuumed from nearly all but the very largest pipes, as well as from the wind chests upon which pipes sit.

pictured above: former parish organist David (who often had assisted Chris with the organ restoration through 2023) vacuuming top of Choir division wind chest, before the installation of HDF panels over deteriorated plaster wall

Chris installing more HDF panels over plaster wall

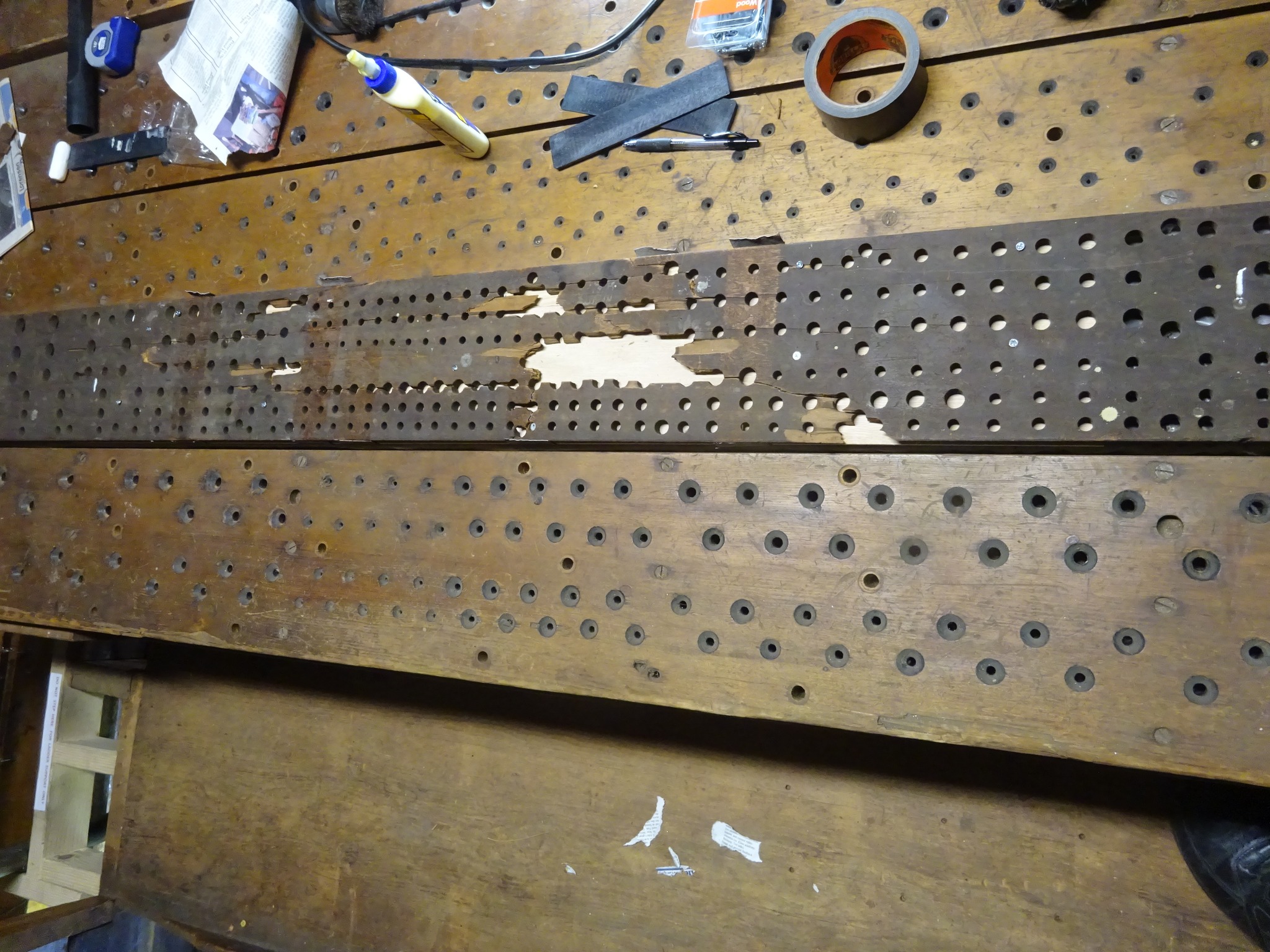

From 2021 to 2023 removed pipes, vacuumed, lubricated toe-boards, sliders, bearer-boards of all slider wind chests. Used traditional graphite for Great, Pedal and Choir divisions; used Protek CLP liquid polymer (similar to PTFE/Teflon®) for Swell division. So this is an on-site test to compare the two products’ durability, etc.

Pictured above: one of 38 Sliders, cleaned and reinstalled with a new coat of black graphite lubricant. The slider (a long, thin piece of mahogany) has holes which correspond to matching holes in the toe board, which fits over the slider. The pipes and supporting pipe rack then sit on the toe board (as can be seen immediately to the right of the exposed slider). When that particular set (rank) of pipes is turned off, the slider’s closed position blocks the holes in the toe board. When the organist wants to use that particular rank, he pulls the stop knob at the console, which causes the slider’s holes to align with the holes in the toe board. So when the organist plays a note, air now can pass from the wind chest’s note channel and into the toe hole of the pipe to sound that note.

In 2023 the Great division and Tuba Minor were covered with hardware cloth “roofs” to protect the organ from the future possibility of falling ceiling plaster:

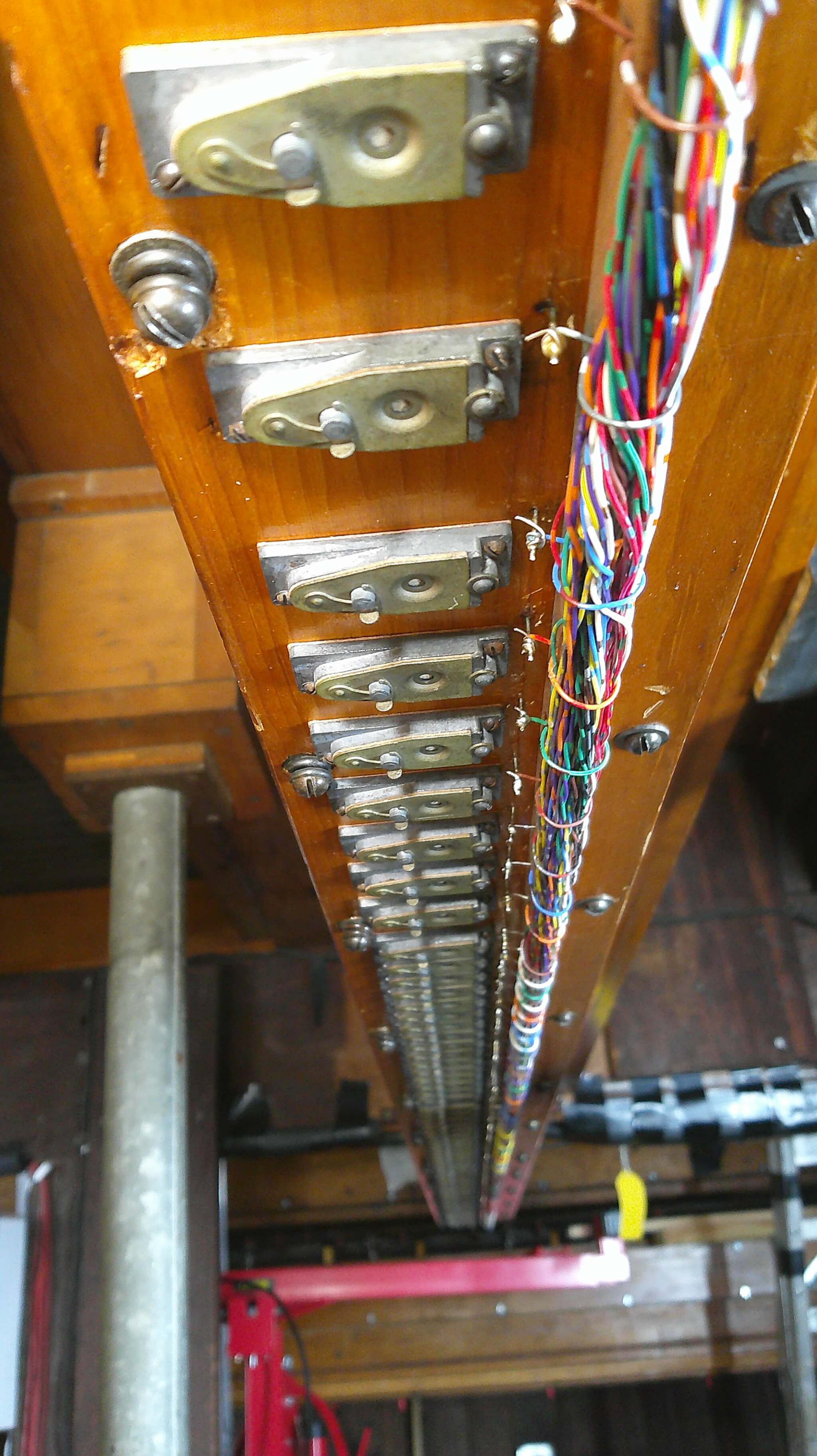

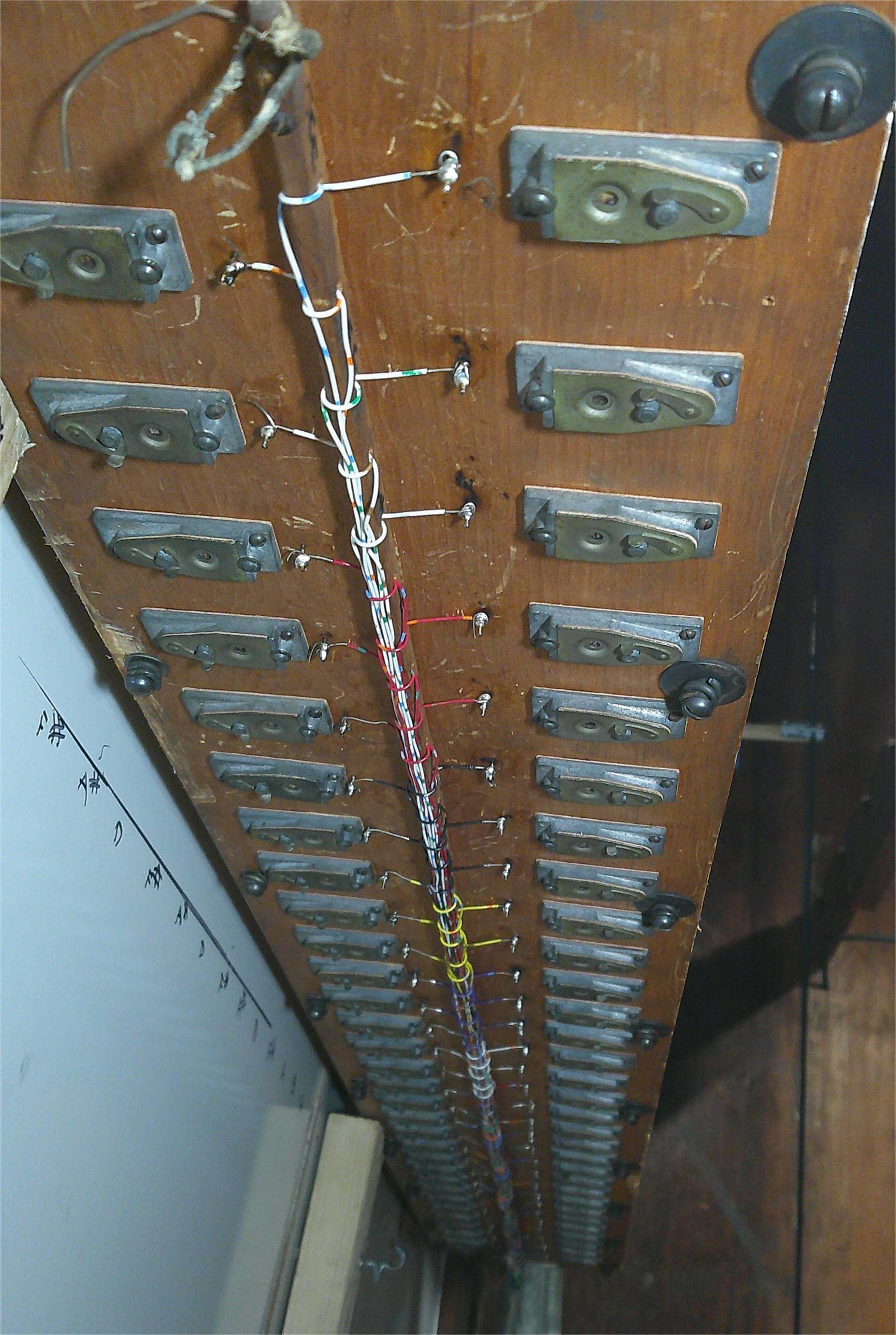

֍CURRENTLY ONGOING: Chris is replacing hundreds of feet of frayed, grey cloth-covered 1923 low voltage wiring:

So far, Chris has completed this on the Great and Swell divisions’ main wind chests, the Swell division’s Vox humana wind chest, the Tuba Minor wind chest and one of the three wind chests of the Great Grand Open Diapason, using color-coded telecommunications (telco, Cat3) cable. Each color combination indicates a specific pitch, which will make it easier to connect each wind chest to a new control system. Some of the wind chests pictured below will need additional work, e.g. new electromagnetic valves aka “magnets”. However, this can be done without removing the new cable:

The opposite end of the cables will be attached to modular connectors particular to the new Control System which will be installed by others later. This installation of new cables to all of the wind chests is an ongoing project which Chris (president of Valley Organ Restoration Co LLC) hopes to complete by the end of 2026. Per usual, updates will be posted here.

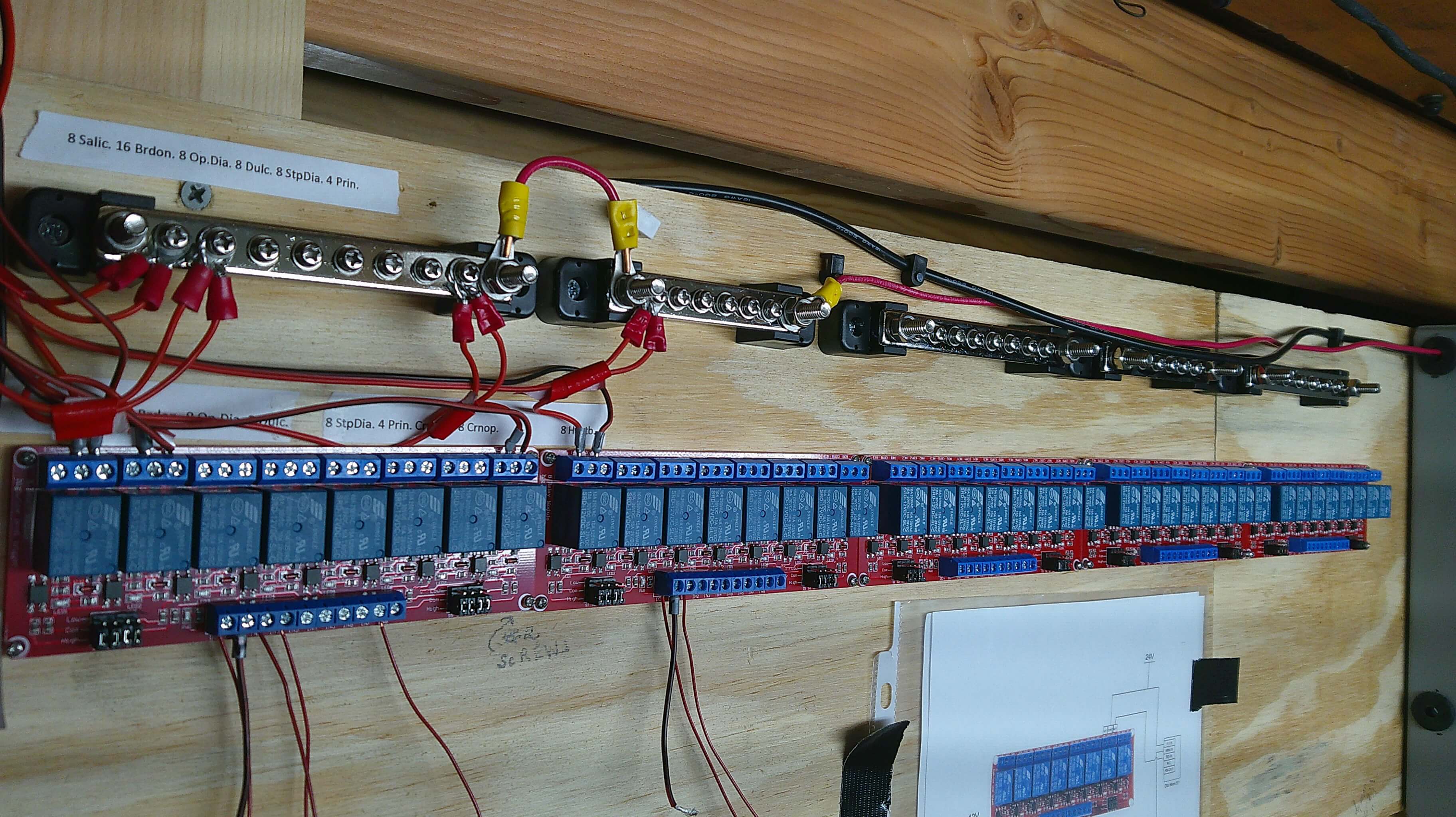

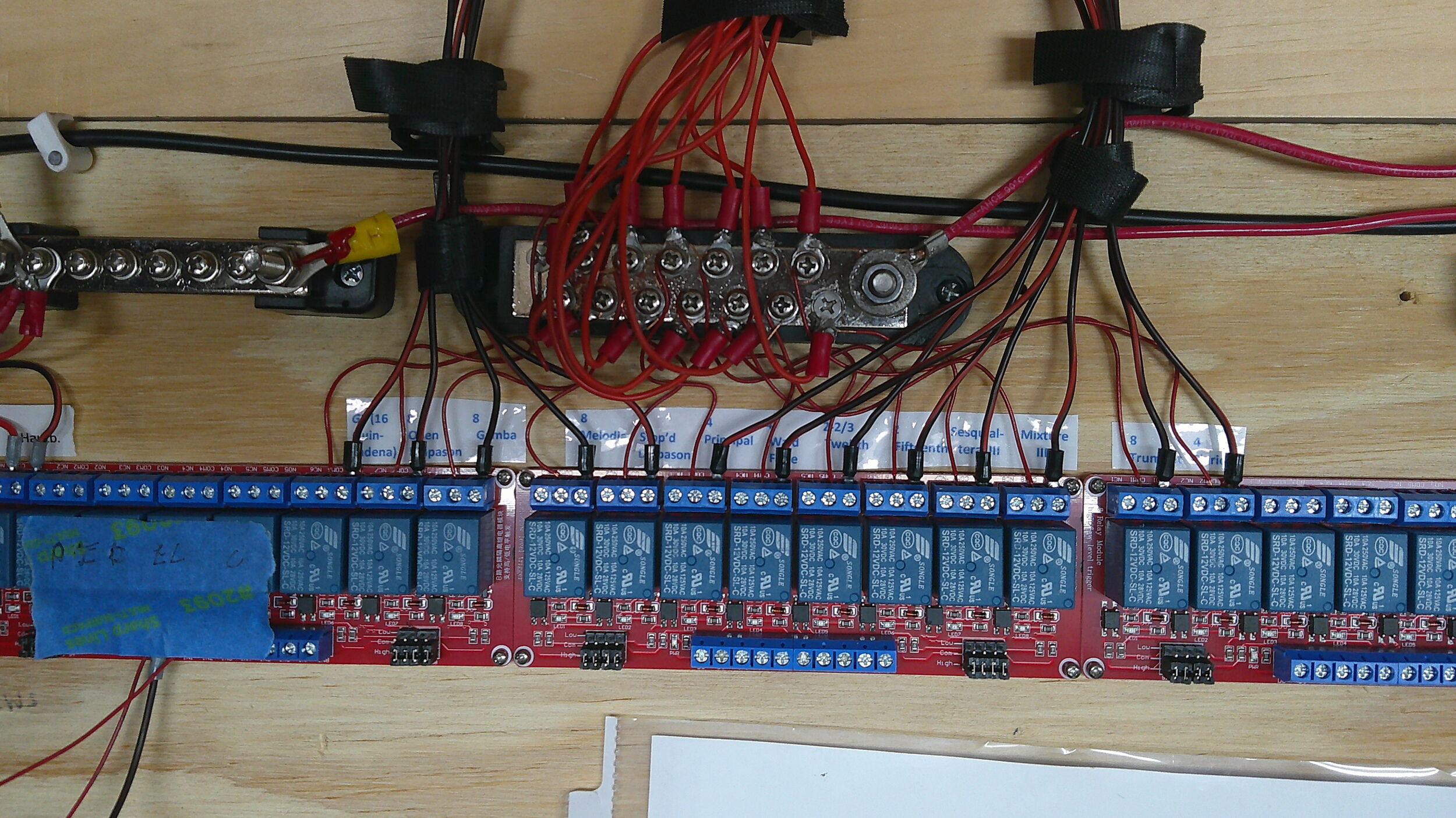

In 2023 Chris installed a new eye-level mount for the future chamber drivers/relays which will replace the 1923 wire spreader board (which is visible at bottom of new mount’s right leg). The solid-state relays/switches for various components will be placed here:

In 2024, on the mount pictured above, Chris installed the relay modules which will control 38 new slider solenoid motors:

On this same mount, Chris installed the 24VDC power supplies for the slider solenoid motors. Ultimately the 38 slider motors, in groups of 12-13, will be powered by these three power supply units:

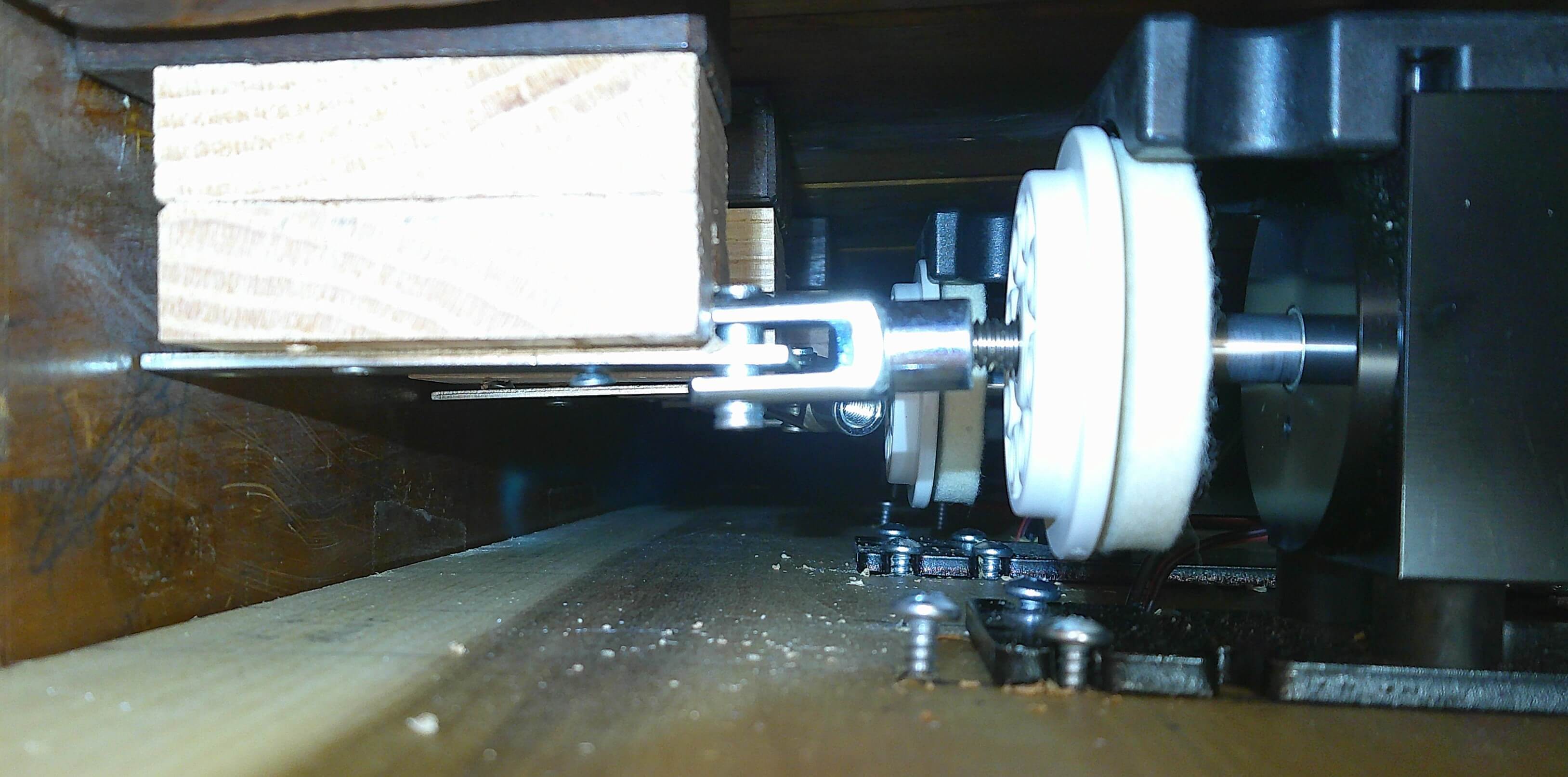

֍CURRENTLY ONGOING: Over the next 2 years Chris will be adding clevis fork and pin assembles and the mounting infrastructure for a total of 38 solenoid slider motors:

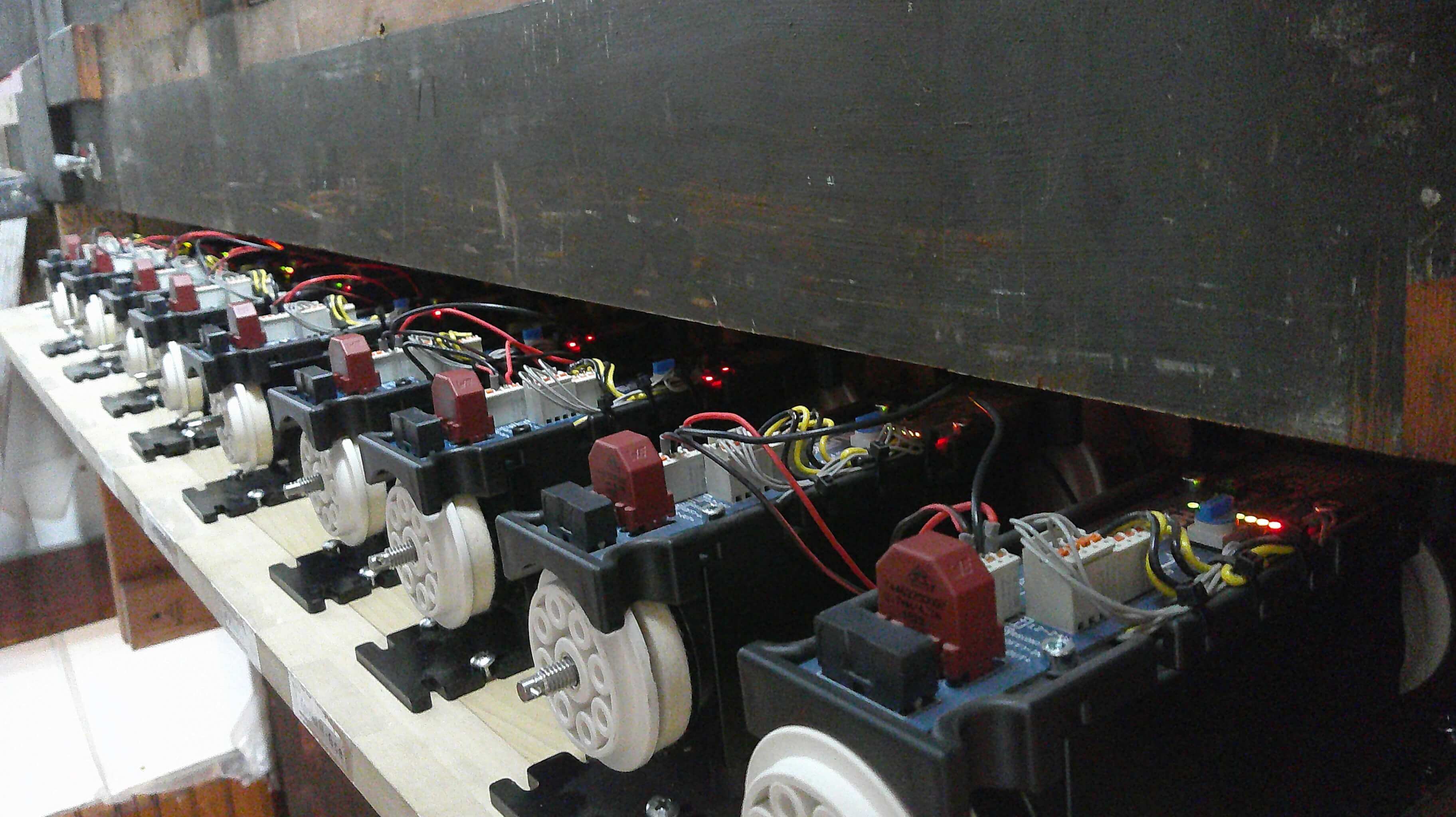

In 2024-25 Chris added 9 German-made solenoid slider motors for the Swell division. These attach to the sliders via the clevis forks pictured above. (Function of sliders is explained above). These slider motors sell for c. $350 each, with materials and labor related to their installation typically bringing the cost of just 9 such motors to c. $10,500. The 9 installed so far have cost your parish nothing. To complete the restoration of this particular organ, a total of 38 slider motors ultimately will be required, a project which Chris, president of Valley Organ Restoration Co, hopes to complete by the end of 2027, with progress posted here:

slider motors on poplar mounting board:

A drywall lift is used to raise the mounting board into operational position:

a slider motor attached to clevis fork and pin:

solenoid slider motors raised into operational position:

removable protective cover placed over solenoid slider motors:

In August 2025 Chris added the mounting structure for the 13 solenoid slider motors to be installed for the Great division. A poplar board with maple supports below it was raised into position, using a drywall lift:

Once in position, the mounting board was held into place with lag bolts and the position of the 13 solenoid slider motors to be installed was marked on the board:

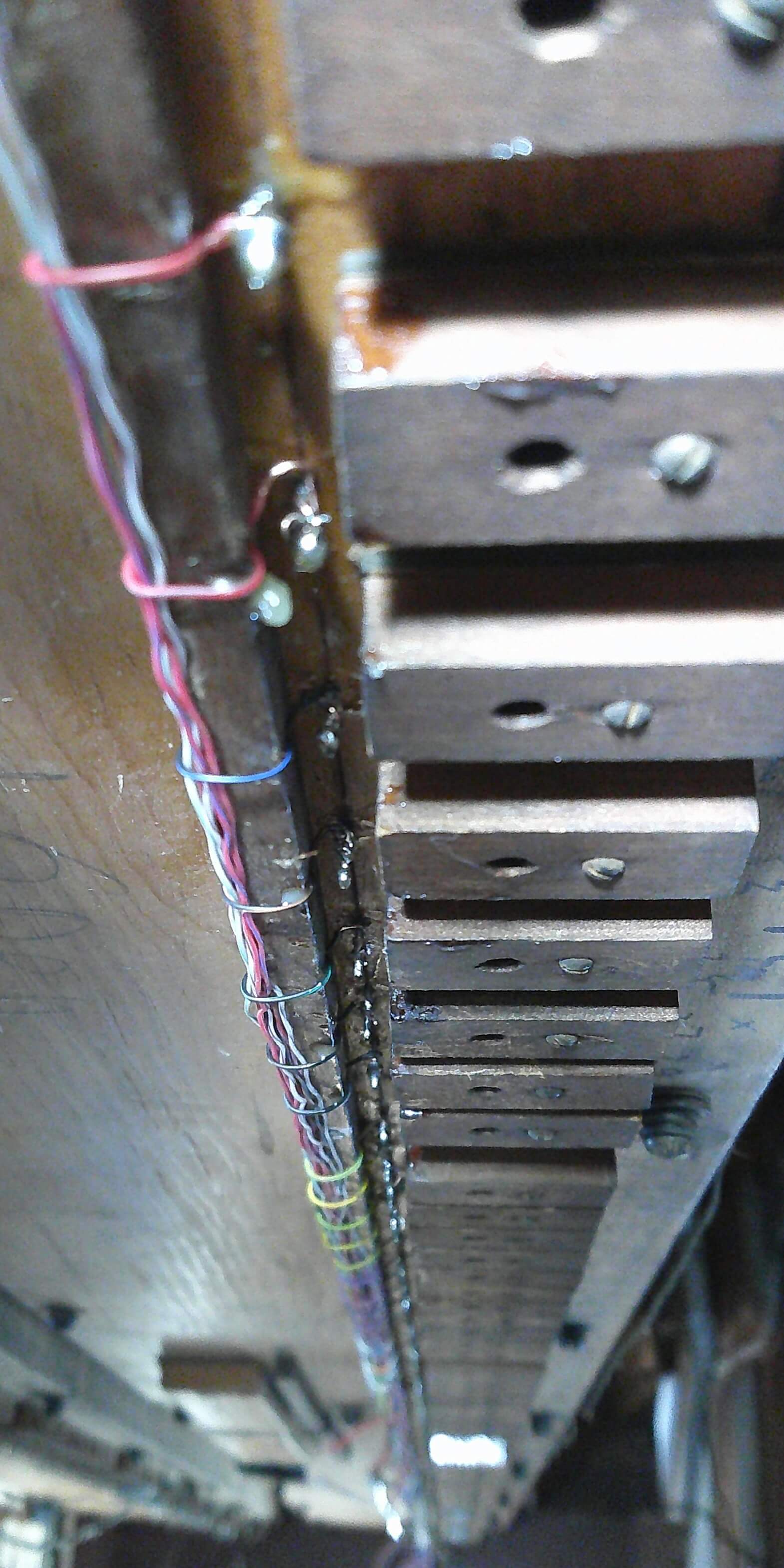

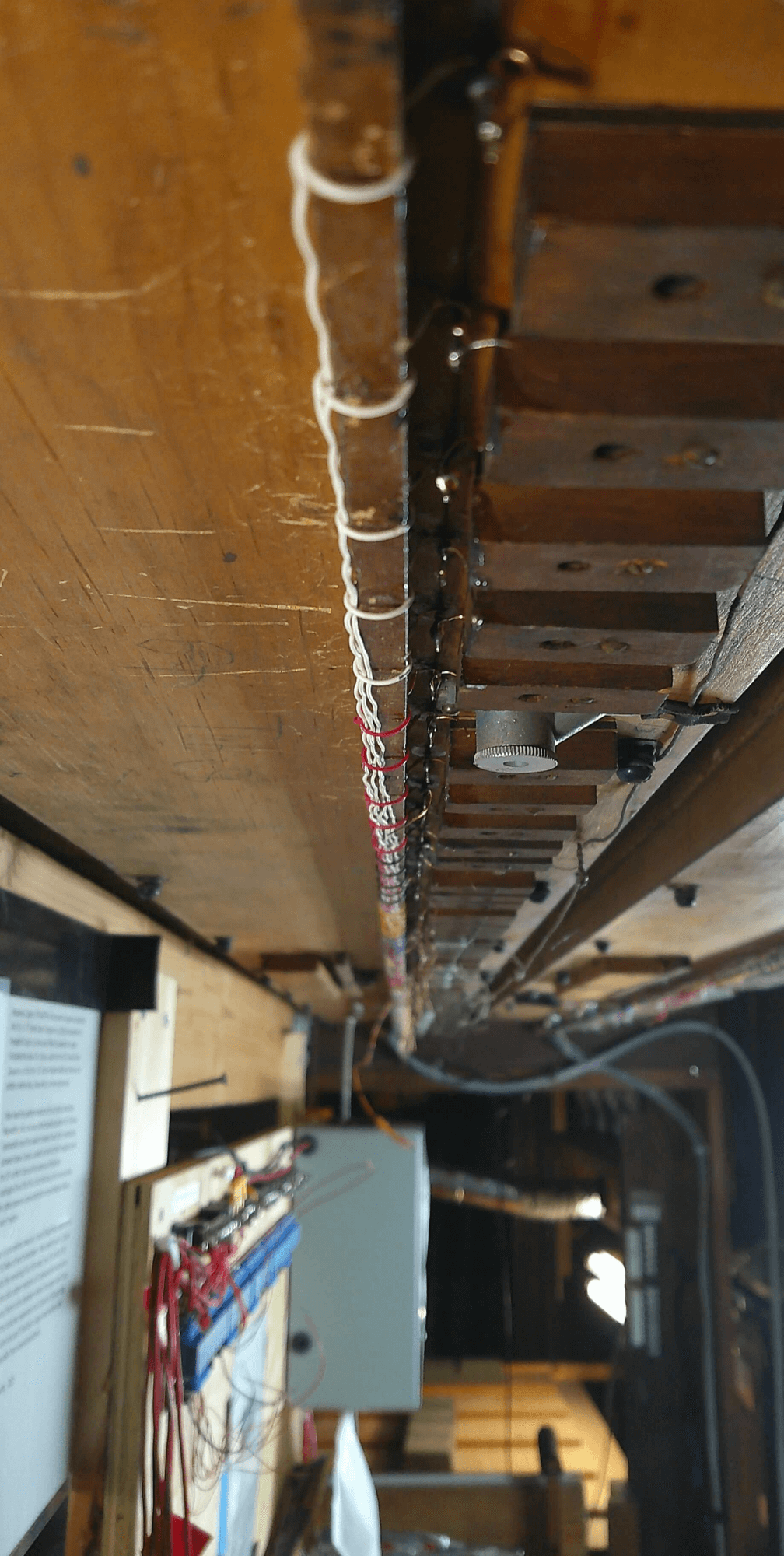

In September 2025 Chris added the wiring for the Great division solenoid slider motors:

The only task left to complete the Great division slider motor work is to install the German-made solenoid slider motors themselves. However, Chris has decided to hold off on ordering any more until the tariff is more predictable. The most labor-intensive and time-consuming aspect of this slider work–and therefore typically the most expensive aspect–is building the support structure and installing the wiring and related components. So, Chris thinks that for now his time will be better spent completing these structures and wiring for the remaining three slider windchests (Choir, Pedal C, Pedal C#), and then ordering the solenoid slider motors.

In October 2025 Chris began removing the Choir division’s non-functional 1923 slider motors:

With the Choir division’s nonfunctional 1923 motors removed, Chris then installed the 8mm clevis forks on oak mounting blocks:

For the new German-made solenoid slider motors, Chris constructed a mounting shelf of poplar and maple, held in place at each end with large pieces of Douglas fir and lag bolts: similar to what he has built for the Swell division and Great division.

In November Chris installed the wiring for the Choir division solenoid slider motors.

wiring at Choir division solenoid slider motor mounting shelf:

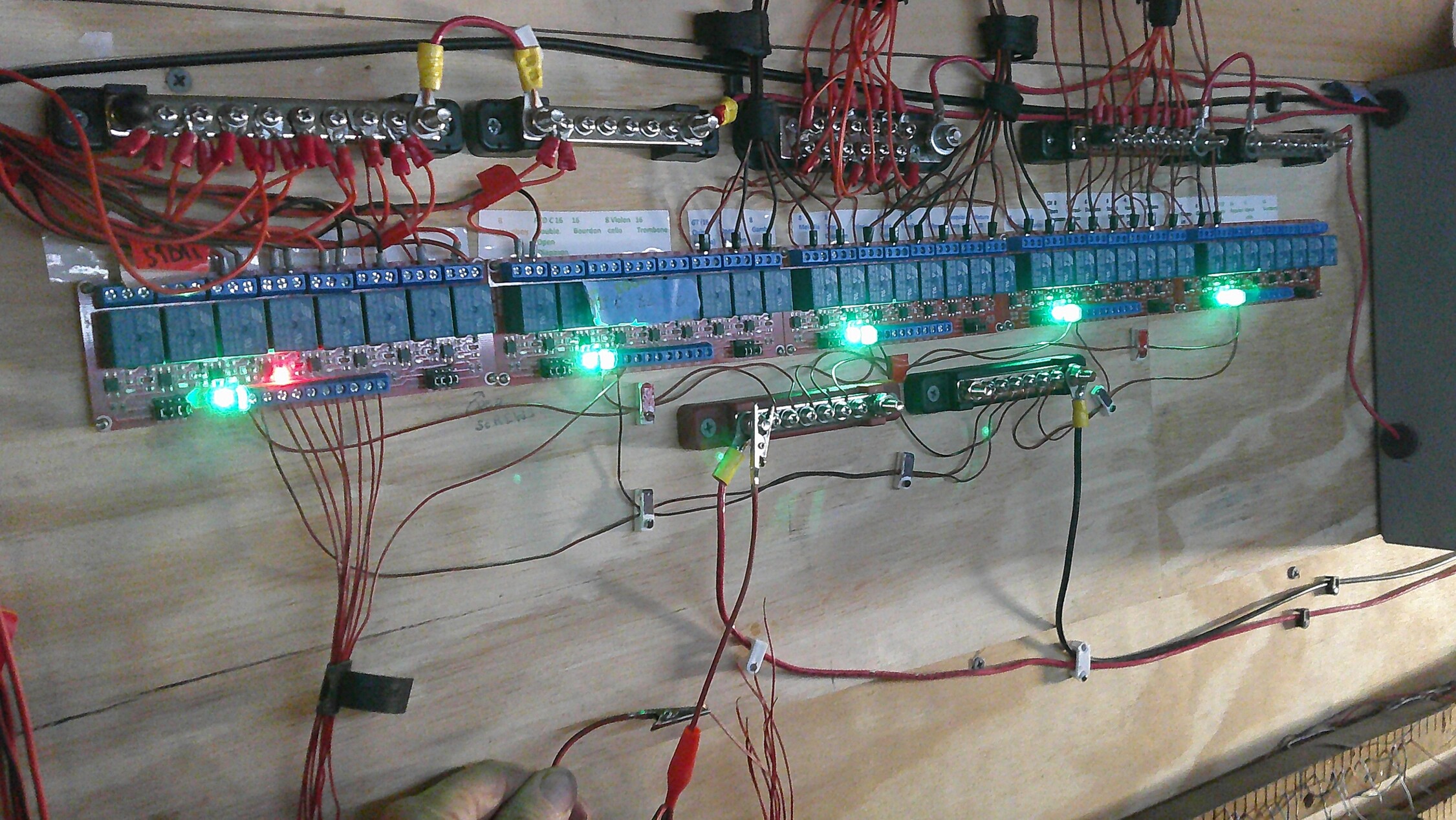

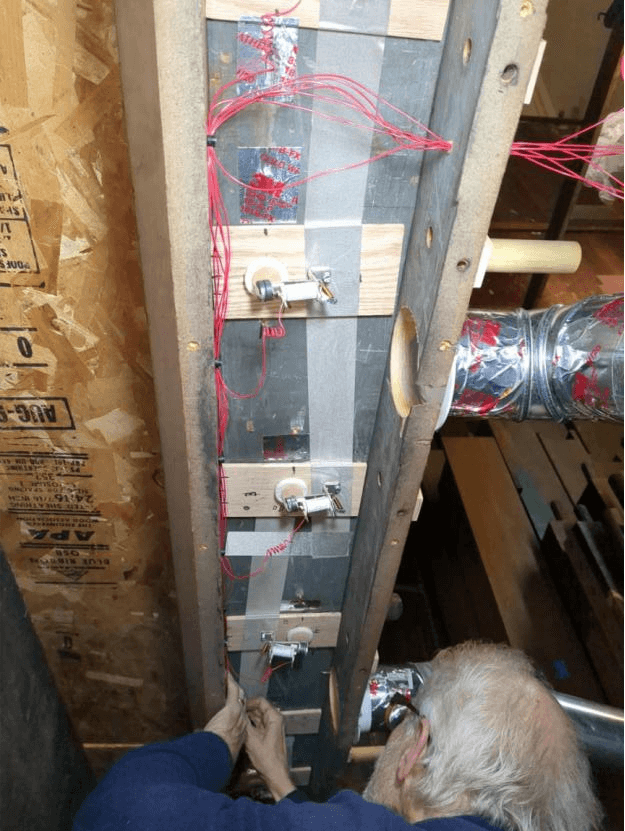

֍֍In December 2025 Chris completed the wiring of the relays (switches) which will activate all thirty-eight 24VDC solenoids, via the 12VDC control system:

In the photo above, the green LED lights indicate that the 12VDC is connected to all five relay modules. The single red LED indicates which slider solenoid has been switched on via one of the three 24VDC power supplies, which are enclosed in the gray NEMA box barely visible on the right. The thin red wires bundled with a piece of black Velcro and descending out of the left bottom of the photo will connect to the future control system’s chamber driver. In the photo above, Chris is testing the system by using an alligator clip connected directly to the 12VDC rectifier, since the 12VDC chamber driver has not yet been installed.

You can follow Chris’ ongoing slider motor installation work in much more detail at this link: https://flic.kr/s/aHBqjCqedB

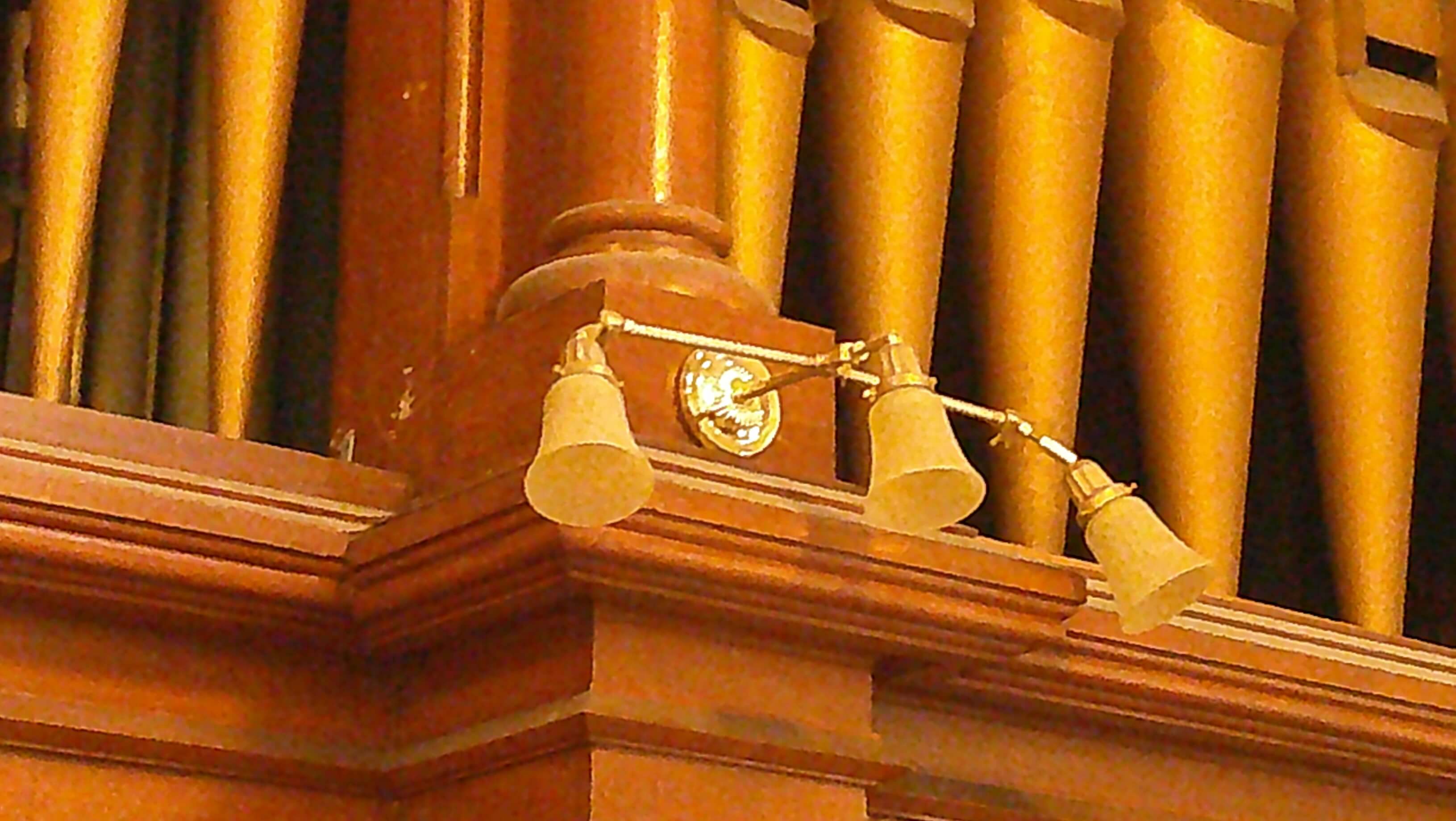

֍In 2025, the unsightly surface-mount cable raceways and track lights mounted on the organ’s façade were removed…

…and new retro-style fixtures were custom made by Christopher Schaefer (president of Valley Organ Restoration Co). These brass fixtures have ‘heads’ that can be adjusted up, down, left, right. Each fixture is supplied with three, 7 Watt LED mini-flood light bulbs, using a total of only 21 Watts per fixture:

In 2021 Chris modified the side of Choir chamber so it can be opened for easier access:

Safety grips near top of access ladders were added. Hazardous walk-boards were reinforced with joists:

Chris reinforcing an 1876 walk-board with new floor joists

Provided new access ladders: 24’ extension, 8’ straight; also a dedicated Shop Vac.

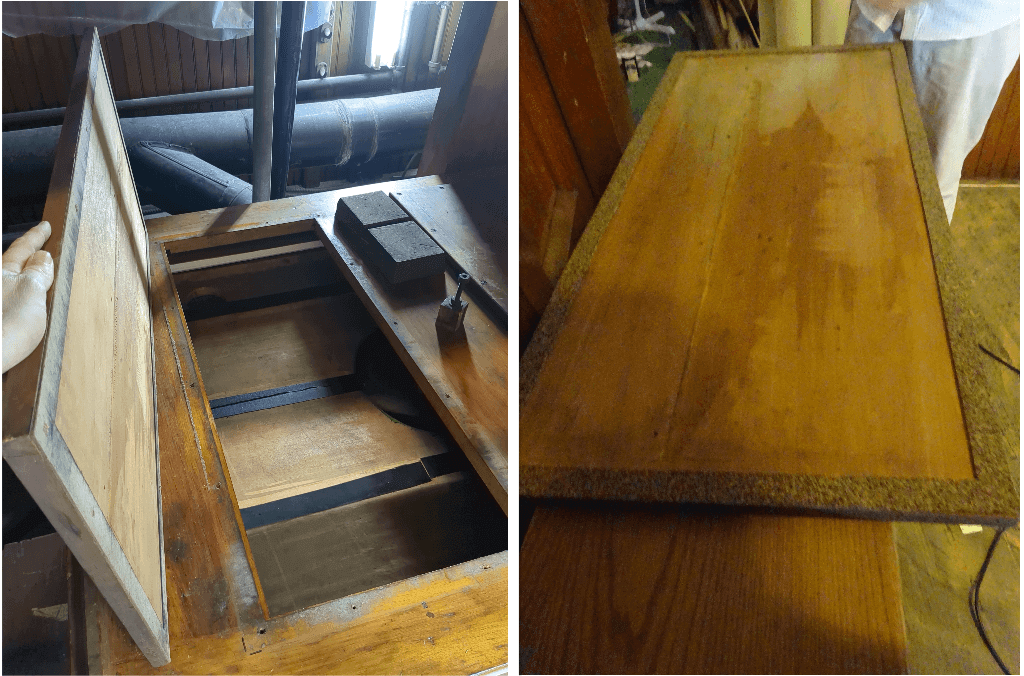

in 2024 Chris constructed a small staircase over the main wind-trunk to facilitate entering the Swell division chamber for tuning and maintenance:

In 2022 Chris designed a temporary platform to facilitate work on large pipes and wind chests of Pedal division:

Pictured above: Chris standing on temporary platform while removing a large Pedal pipe

Chris upgraded/added electrical outlets inside organ and in loft.

He replaced all florescent lighting inside organ with energy-efficient LEDs and rewired circuitry so that all work lights now are controlled by a single illuminated light switch.

Posted circuitry map inside organ, identifying which circuit breaker controls which lights, outlets and organ components.

Modified one case front panel with handles and magnetic catches, and enlarged and increased existing floor openings between console and front of organ case, to facilitate running cables from inside organ to console.

All pallet (note valve) pull-down wires were lubricated with Protek CLP polymer (similar to Teflon®):

Chris lubricating pallet pull-down wires:

To increase potential air flow (CFM/cubic feet per minute), Chris replaced 3-inch diameter air supply (“wind conductor”) to Tuba Minor and Great Grand Open Diapason with 4-inch diameter wind conductor (for wind which originates from separate vertical reservoir serving these 2 ranks only).

Chris replaced non-functional, Jerry-rigged electro-pneumatic valve system of 14 Grand (aka Double) Open Diapason “tower” pipes of façade with 14 Peterson electromagnetic Super Valves (which ultimately will be doubled to provide adequate air to these huge pipes):

In 2023 Chris replaced one 6-note 1923 electro-pneumatic façade wind chest with rebuilt, re-positioned electromagnetic (“direct electric”) wind chest and relocated part of façade structural support, to free up front most bearer and slider of Great wind chest. This will allow the possibility of someday adding an additional rank to the Great division. It also will make it easier to remove the Great wind chest when it someday needs an extensive overhaul.

12 leather pneumatic pouches of pedal 16-foot Trombone (1923 extension of Great 8’ Tuba Minor) were replaced:

Pictured above: Chris testing new leather pouches for leaks

In 2023 Chris replaced 4 missing stops in Great:

Mixture III, Sesquialtera III, 8’ Trumpet, 4’ Clarion with salvaged pipework: Sesquialtera from 1870s, others from mid 20th c. (Approx. 50 small flue pipes, between c4 and a4, still need to be replaced in these 4 stops.)

in 2023 Chris also Replaced 2 missing stops in Swell:

Cornet III, 8’ Cornopean with salvaged pipework: Cornet from 1870s-1880s, Cornopean from early 20th c.

So, Chris (president of Valley Organ Restoration Co) replaced a total of nearly 700 missing pipes: twelve, 58-note sets (“ranks”) of pipes, comprising over 1/3rd of the organ! (The original pipes had been removed by Peragallo Organ Co in 1923.) If new, these would cost a minimum of $200,000! What Valley Organ Restoration Co LLC charged your parish: $0

Pictured below: one of 4 cargo van loads of salvaged organ pipes, saved from various dismantled/destroyed organs, and obtained by Valley Organ Restoration Co from organ companies in New York, Maryland and Pennsylvania:

Chris arriving at St. Patrick’s with another cargo van full of salvaged organ pipes:

The salvaged pipes largely have restored the organ’s original 1876 specifications (list of pipe sets, aka “ranks”), which has been one of the goals of the current restoration project. However, the pipes’ scaling is not identical to the 1876 originals. Scaling is the ratio of an organ pipe’s diameter to its length and affects its tonal characteristics. While a museum-quality restoration, recreating every detail of the 1876 original, is beyond the scope of this current organ restoration project, the ongoing work is an attempt to maintain the overall tonal design and characteristics of a large 19th century organ. Of course, the primary goal is to have the organ playable for the first time in several decades!

Pictured below: The salvaged 4′ Clarion; its new supporting pipe rack was constructed by Chris Schaefer, president of Valley Organ Restoration Co.

In 2025 Chris installed a 13th salvaged rank: a c. 1908 Dulciana rank, to be used as a céleste (i.e. tuned slightly sharp to create a gentle undulating effect) when used with Erben’s 1876 Dulciana. This was placed in the original location of Erben’s 1876 Vox humana which Peragallo had relocated in 1923 to a separate small wind chest. Therefore, this Dulciana céleste has been added without replacing any of Erben’s original 1876 pipework:

In 2021 a 1927 E.M. Skinner, 3-manual & pedal, pipe organ console was procured at no cost to your parish. This console was gutted & refitted c. 2007 with new draw knobs/Stop Action Magnets (SAMs) & keyboard electrical contacts. The console currently is used to control recorded (“sampled”) imitation pipe organ sounds, played through speakers, which is what you currently hear on Sunday morning. However, the keyboards’ and draw knobs’ modular electrical connectors easily can be attached to a new solid-state Pipe Organ control system.

This refurbished console (pictured below), provided at no cost to your parish, ultimately will be connected to your parish pipe organ:

Several broken shade dogs of Swell and Choir were replaced with custom reproductions made by Abbé Kevin Kerscher, ICKSP. Leftmost in photo below is original, the others are Abbé Kevin’s reproductions:

Pictured below: a new shade dog installed. The shade dogs are part of the pivot system which opens and closes the shades, allowing the organist to control the volume of the pipes behind the shades:

In 2023 Chris modified the shade dogs of Swell and Choir divisions, replacing screws or removable pivot pins with fixed steel dowel pins, and he relocated the Choir division shade dogs several feet lower. With these modifications the trace rod now merely can be lifted off, making it easier to remove shades in front of Swell and Choir chambers when doing maintenance or repairs inside the chambers:

Photo above: Horizontal trace rod is fitted over steel dowel pins of shade dogs, so all 11 shades open or close simultaneously. Later, Chris connected the trace rod to a new shade motor (pictured below) to be controlled by the organist via a foot pedal at the console.

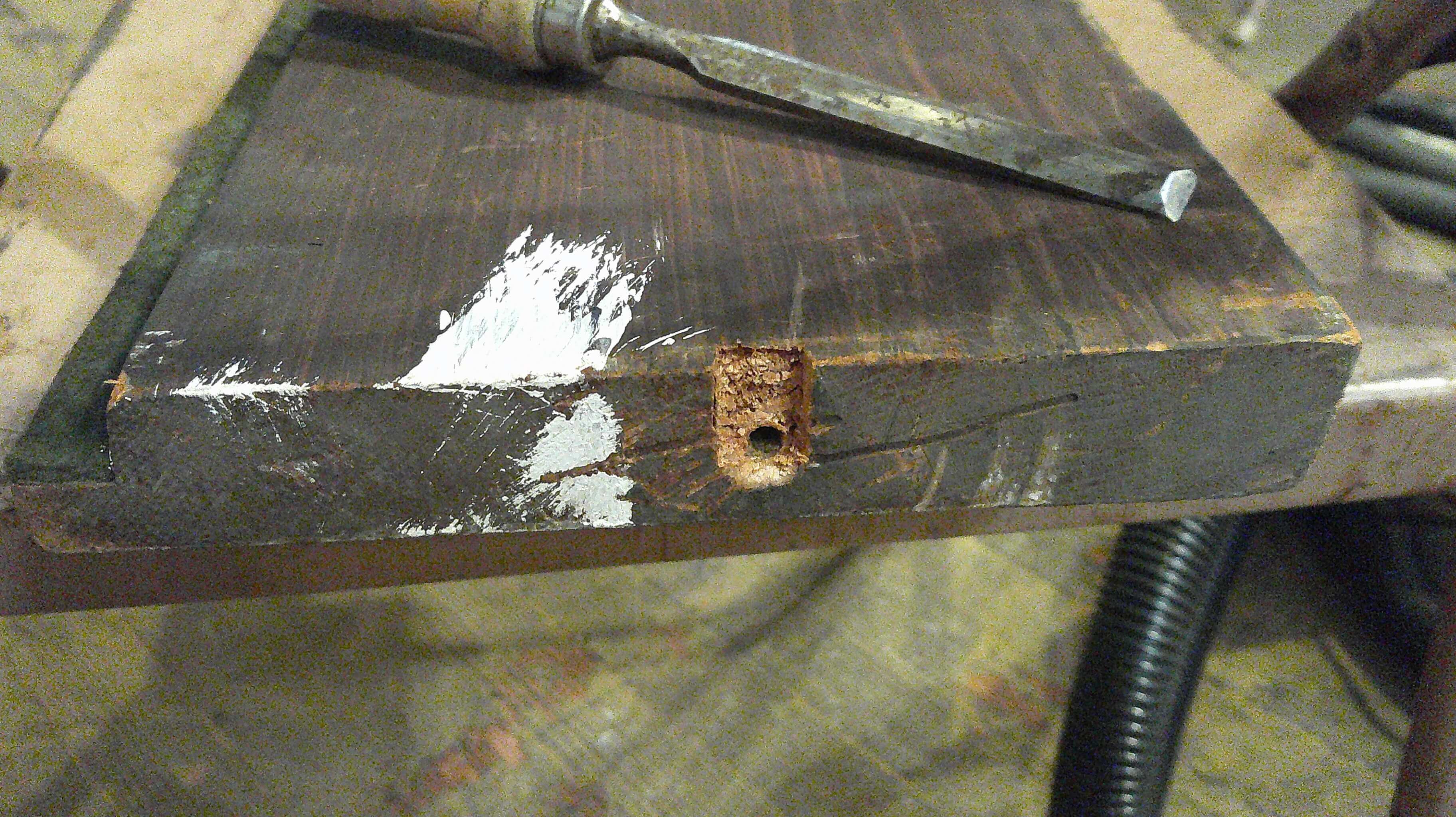

Steel washers of bottom pivot pins of Swell and Choir shades were replaced with Teflon® (PTFE) washers, so shades move much more smoothly. Chris also chiselled a channel into top of Swell division shades to make it easier to slide top pivot pin into place when reinstalling shade:

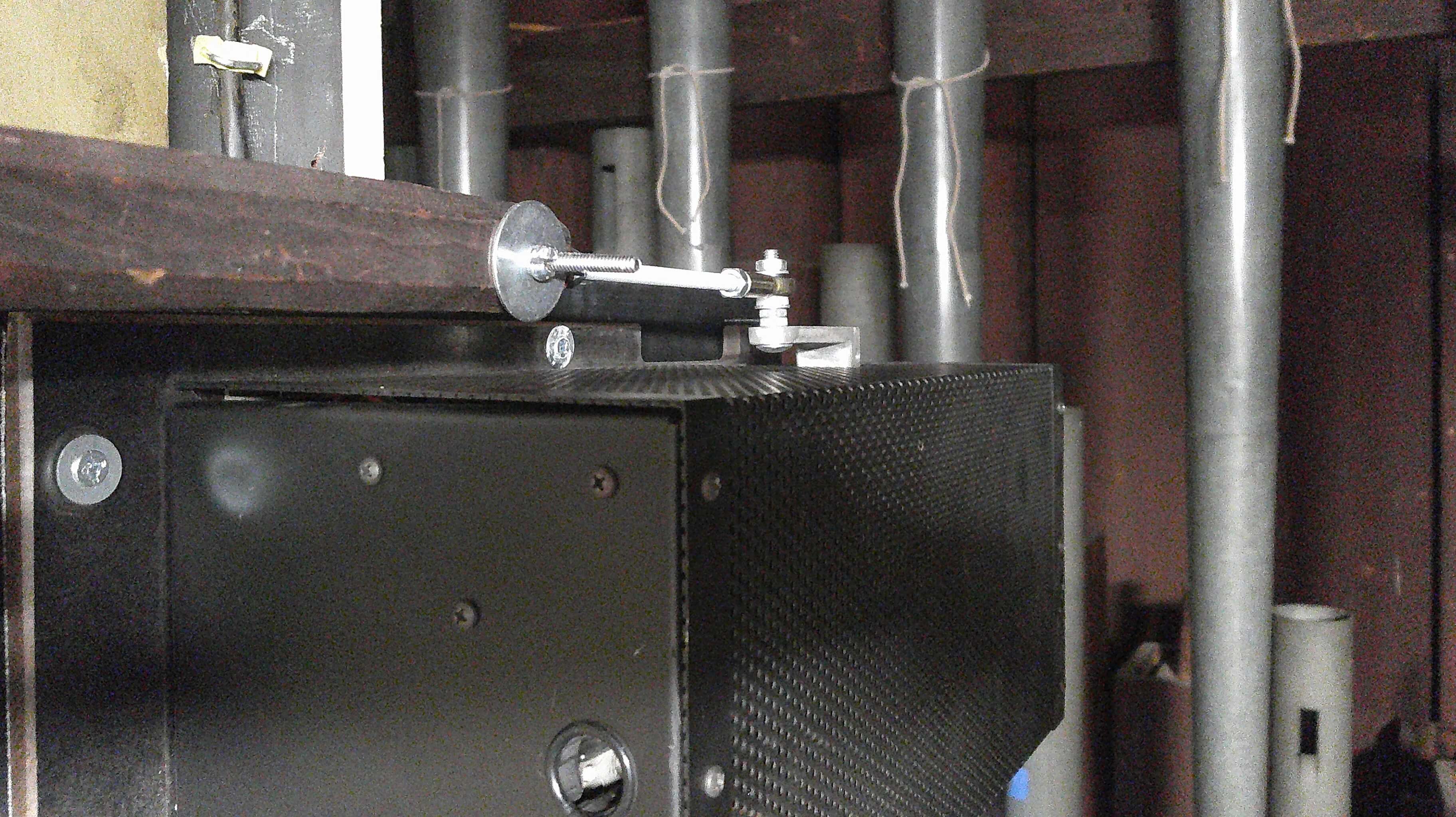

In 2024 Chris installed shade motors for Swell and Choir shades, replacing the 1923 whiffletree motors which no longer worked. The two motors were procured by Valley Organ Restoration Co, at no cost to your parish, from a recently dismantled but well-maintained organ in Pennsylvania:

.

Chris performed minor, miscellaneous DC electrical repairs/re-soldering.

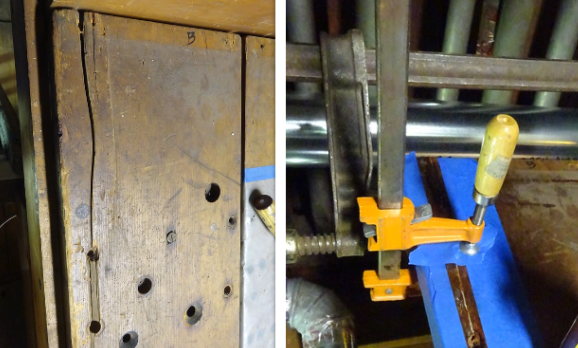

Chris repaired the worst cracks in pipe racks; reassembled pipe rack of Great division’s Mixture and Sesquialtera. The pipe rack holds the organ pipes in an upright position:

Before:

After:

Before:

After:

Chris repaired the cracked toe board of Great Trumpet/Clarion and performed additional miscellaneous carpentry work:

Chris realigned & felted the holes of the Double Open Diapason Extension pipe rack. He also replaced the missing pipe rack of Great 4’ Clarion by constructing a new one, pictured below:

Approximately 20 pipe stoppers that had fallen into wooden pipes were releathered. These stoppers are used to tune ‘stopped’ wooden pipes, by moving the stopper up or down:

Chris constructed new “perches” down center of Great and Swell divisions to facilitate tuning, etc:

Some of the leaking leather panel gaskets of the reservoirs (wind pressure regulators) were replaced with new Nitrile-cork (aka Buna rubber-cork) composite gaskets:

Chris removed dents in several dozen metal pipes in Swell division. These pipes had been damaged by an organ tuner who had no training to do such work:

Chris re-soldered broken solder joints in approximately 10 pipes in Swell division.

When accessing a component to clean etc, replaced most of the 1876 slotted screws with new Phillips screws of same size and head type, to facilitate future access.

Chris installed a new DC fuse box from 12V rectifier to power keyboard, slider motor relays, etc.

He installed a new air switch to turn on the 12VDC rectifier when blower is turned on:

Chris created a permanent loft workshop for his company, Valley Organ Restoration Co, to perform minor, ongoing organ repairs, e.g. releathering wooden pipe stoppers and smaller components:

֍ Summary updated through December 13, 2025 ֍ Approximate value of labor and materials (i.e. what most organ companies would charge) for the work listed above: c. $275,000. Amount which Valley Organ Restoration Co has charged your parish thus far, for both labor and materials: $535

tasks which another organ company will need to do for the organ finally to be playable (in 2028?):

- Install a new solid-state control system, connecting the console (keyboards) to the windchests

- repair some of the more heavily damaged metal pipes and replace some of the small pipes which are missing

- regulate, revoice some of the pipes (particularly those which Chris salvaged from from approximately 8 other organs which had been destroyed), so that all of the pipes ‘speak’ properly and blend with the rest of the organ

- Replace the round leather ‘pouches’ which open and close the air valves under pipes of 3 or 4 windchests

- Replace the obsolete wooden electromagnetic valves (‘magnets’) of 2 windchests

- tune the entire organ, likely for the first time in over 100 years!

- Chris currently estimates that all of the above will cost c. $85,000, ideally paid for via donations specifically for this project. (This estimate assumes that by 2027 Chris will have finished rewiring the windchests and installing the remaining 29 slider motors, while maintaining his current pace of working on the organ one 8-hour day per week.)

- Ideally a company would be contracted for the above items in 2027, with the work commencing in 2028–in time for the 125th anniversary of this church’s dedication! (and Chris’ 75th birthday!!)

Photo above: organ repair contractor Christopher Schaefer (President & founder of Valley Organ Restoration Co and Project Director) resting his hand on the largest wooden pipe inside St. Pat’s organ. It’s c. 17 feet tall and weighs over 200 lbs. Chris had to lift the pipe out of its toeboard opening and then pull the bottom of the pipe out about 12″ (as he did with the 3 pipes to its left) so he could crawl behind these pipes to do some repairs.

Chris, pictured above, covered with century-old soot after moving that heavy pipe!

Chris kneeling to do some repairs behind that huge pipe he moved

For the history of this organ go here:

About the Waterbury Erben organ – 1876 Henry Erben Organ Waterbury CT

For much more detailed photo albums of ongoing restoration, go here:

Detailed photo albums – 1876 Henry Erben Organ Waterbury CT

To see how you can help, go here:

Organ restoration: How You Can Help… – 1876 Henry Erben Organ Waterbury CT